Construction Department

QA/QC POLICY

The quality management system of our company has established and maintained in order to achieve continual improvements. Our aim is to meet project requirements by providing services that are undertaken to the highest professional standards, represent value for money and are delivered on time. We shall pursue this aim through implementation of a quality management system involving all staff that will require;

• To improve the customer satisfaction level.

• To improve delivery of services to the client

• Continuous Orientation

• To improve the overall effectiveness of the organization through reduction of non-conformities

Also, it is our policy that the facilities should be installed in strict Conformance with the drawings, industrial standards & specifications. Local regulations and good construction practice during all phases of construction and that to achieve this goal, and effective quality control and assurance plan be prepared and strictly adhered at all time.

We considered that establishing and maintenance for and effective construction quality control is our major responsibility, which starts with project manager progressing through his staff down to each craft. Also, effectively perform quality control activities.

These general objectives are made measurable which should be achieved on time. The measurable objectives are split up as targets at relevant functions and levels in the organization. These objectives are achieved within the time frame through the proper communication of the objectives and facilitate the contribution of each individual towards the continual improvement of the system

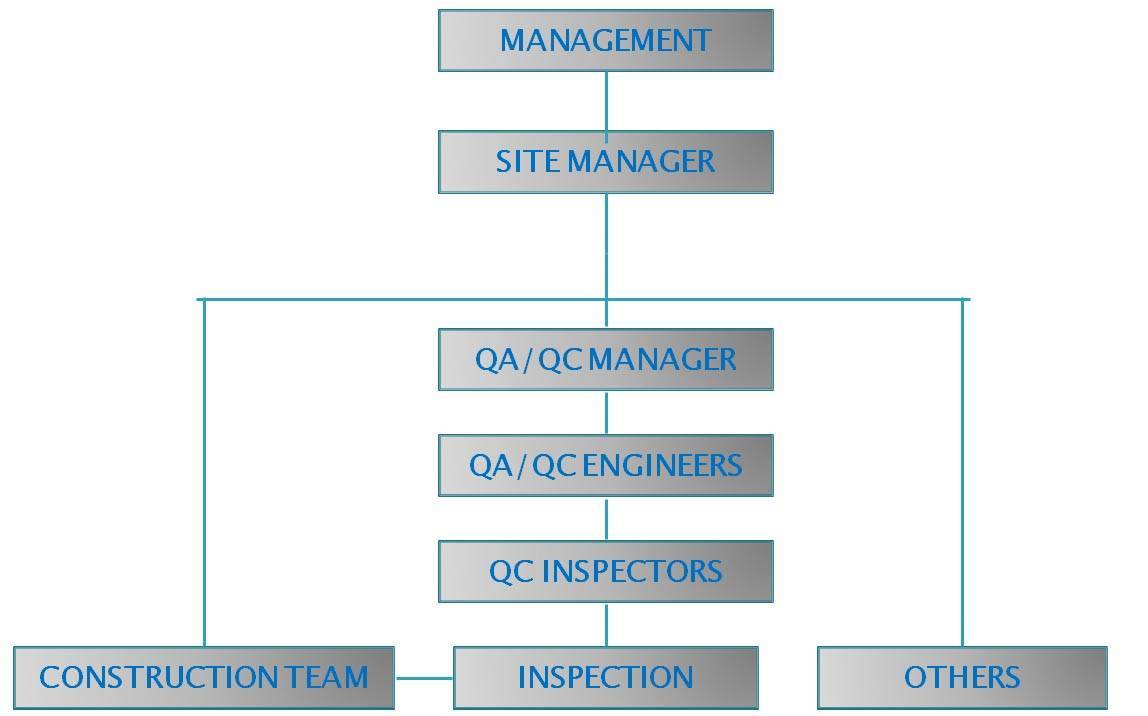

Organization Chart

X-SMART Construction Department consist of QA/QC Manager & Engineer who are the key staff members to our management team and quality controls from each discipline who are technically qualified to check the work and standards

Documents covering all QA/QC activities must be witnessed by client authorized representatives.

QA/QC Activities

Following is the brief summary of inspection and test activities required to ensure the quality and compliance of the construction mechanical installation and fabrication as per the drawings and specifications.

GENERAL

• Tests and certification of craftsmen

• Preparation of work procedures/method statements and job

• Instructions.

• Material control and verification.

• Preparation and follow up of its own punch list before punch out.

• Coordinates internal quality audits on project to verify implementation of the work instructions & project quality requirements and follow-up

• Submit weekly and monthly reports to client.

• Submit two week look ahead schedule for construction and pre-Commissioning activities.

• Monitoring welder’s status logbook and performance report welder’s report.

• Coordinates NDT activities.

• Check maintenance and clearing of works.

CIVIL WORKS

• Check cleanliness before backfilling.

• Compaction test for sub-grade and back filling.

• Check re-bar and form work prior to concrete pouring

• Preparation of bar bending schedules

• Asphalt related tests

CONCRETE

• Preparing weekly forecast of concrete requirement

• Check cutting, bending & placing of reinforcing bars

• Check insertion, placing and fixing of anchor bolts & plates

• Testing and preparing of test cylinders of concrete (Slump, temperature,

• Timing & placing, cylinder crushing test etc.)

• Survey check including coordinates and elevation.

• Dimensions of structures

• Preparing checklist and verify at site.

• Visual inspection for curing and concrete surface

MECHANICAL WORK

• Verify the construction drawings and MTO to identify the materials.

• Ensure the use of correct material.

• Inspect all materials for correct type and damages.

• Coordinate the construction activities as per schedule.

• Checking and inspection of pipe spool fit-up

• Checking erection of spool fit-up. Fit up.

• Checking and inspection of on-going works.

• Monitoring welder performance

• Verification of welding parameters

• Verification of NDT reports

G.R.P.PIPING

• Check excavation, sub-grade elevation & compaction

• Preparation of pipe bedding & compaction test

• Check laying of pipe (Lifting, placing & alignment-coordinates)

• Thickness of lamination and barcol (Hardness) test after curing

• Hydrostatic pressure testing.

• Backfilling layer by layer with suitable material and compaction & testing

HSE Policy

It is emphasized that the content of this manual is a basic “X-SMART” policy an the proper implementation and compliance to the procedures and standards herein prescribe.Health and Safety Plan

X-SMART’s policy is to provide a safe and healthy working environment for its staff, visitors and neighbors. Our full policy statement demonstrates this commitment.• This policy is fully compatible and shall apply to all staff members of the company.

• X-SMART shall provide and maintain a working environment that is as safe and healthy as reasonably practicable at all places where the company’s staff or representative may work, both for our staff members, client or third parties using those facilities under our control or influence.

• The company goals of client satisfaction, ongoing business development and long -term profitability are not in conflict with good safety practices. On the contrary, a good safety record is of great benefit to our business, whilst a safe and healthy working environment protects and encourages people, our most important asset.

• X-SMART in all its undertakings, experience has proved that the safe and efficient performance of work is more profitable and less time consuming than the “slipshod” approach. In recognition of this precept, company will constantly work toward;

• To prevent accident or incident and to markedly minimize hazards during the entire duration of the project, the safety organization of RAYAN will work closely with the client in the implementation of this policy and/or any other project safety policy to further alleviate the construction safety.

• All relevant statutory requirements will be complied with, at all times. These will be considered as a minimum standard and where reasonably practicable will be exceeded where it is necessary to meet the spirit of this policy.

Environmental Policy

X-SMART is committed to sound environmental performance by minimizing the impact of our activities, products or services on the environment. Our goal is to reduce waste, emission and discharges, and use energy efficiently. We recognize each one of us is responsible for conducting our daily business in a way that allows us to achieve our goal. We seek continual improvement and the adoption of industry-best practice in to all our environment control systems. We shall comply with relevant environmental legislation and regulation.Environmental effects can be to land, water or air. Additionally nuisance (noise, dust, etc.) at the boundary fence has an environmental impact on neighbors.

The design of new buildings and refurbishment of existing ones will be effected with due regard to good building practice, energy conservation, minimum wastage of resources and safe systems of collection of pollutants.

Safety Training and Development

The project in-charge has the responsibility to ensure that all applicable safety regulations are made known and complied with on this project. He shall also promote individual safety awareness in an effort to recognize and eliminate unsafe working conditions and practices, which may not be specially covered in the regulations.

The safety Manager shall make request to visit the work sites to enforce the training program. Training is an integral part of the day-to-day job training, which he administers to the men working under his direction. Safety Officer shall point out safety hazards inherent in the work to be done, and shall familiarize his men with the tools and equipment which shall be used in doing the work, particularly stressing correct and safe operating procedures.

Project Image Gallery